Why is acrylic so expensive?

Anything, materials and crafts are often difficult to see through at a glance, personally experienced to know a penny, a penny of goods, completely different enjoyment, as well as the added value of products.

1.The impact resistance of acrylic is very strong, is 100 times of glass, is 16 times of tempered glass, and the thickness of acrylic sheet can do more than 600mm, tempered glass can only do 20mm at most. Impact resistance is not in the same league. The windshield of the aircraft is acrylic, is to value its safety and light transmission. Toughened glass itself has 3‰ self explosion rate, try to ask which aircraft dare to try, once self explosion consequences unimaginable.

2.Acrylic light transmittance is very good, the general glass light transmittance is 82-89%, the best super white glass can only reach 89%. Acrylic light transmittance up to 95%, light transmittance soft, good visual effect. Now many cutting-edge weapons of optical sight, high precision optical lenses are made of acrylic.

3.Acrylic also has good processing performance, can be mechanical processing, can be hot forming, can be injected with special formula stock solution to achieve seamless splicing, can meet the requirements of larger size transparent whole plate, and is not affected by transportation and space conditions. Toughened glass can not be reprocessed, cut and splicing, the maximum size of the universal manufacturer of toughened glass can do 6.8m*2.5m, because it can not be seamless splicing, so it can not meet the requirements of larger size transparent whole board, only acrylic can be achieved.

Acrylic is a kind of high polymer, has all the advantages of glass, in many occasions can replace glass; And the main component of glass is silica, can not replace acrylic. You have a reason to be expensive.

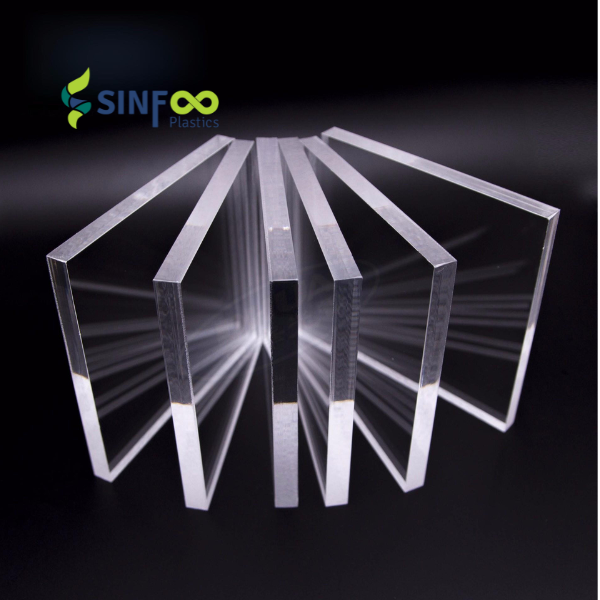

But acrylic materials also have very obvious shortcomings, because of the difficulty of acrylic production, high cost, so there are a lot of quality cheap substitutes on the market. These substitutes are also known as "acrylics", which are actually ordinary organic or composite panels (also known as sandwich panels). Ordinary organic plate with ordinary organic glass cracking material and pigment casting, surface hardness is low, easy to fade, with fine sand polishing effect is poor. The composite plate has only a thin layer of acrylic on the surface, and the middle is ABS plastic, which is easy to delaminate under the influence of thermal expansion and cold contraction. True and false acrylic, from the plate section of the subtle color difference and polishing effect to identify.

Acrylic sheet is good or bad discrimination

1, transmittance identification: good acrylic sheet with white light irradiation, the light is very pure, no yellowed or blue, and good plate transmittance is greater. Pure new material acrylic plate appearance pure color, regeneration plate appearance yellowing.

2, thickness identification: an important characteristic of acrylic sheet is measured by thickness, usually said how thick is enough thickness, choose and buy must ask the thickness, this is the key factor. Pure new material acrylic sheet surface hardness and scratch resistance performance is excellent, cutting without stimulation smell; The surface of the regeneration plate is easy to scratch, cutting when the smell of stimulation.

3, fire identification: good acrylic is not suitable for burning, and will not produce bad smell when processing. Many of the materials on the market are fake, and this one can be tried with what they call scrap. Pure new material acrylic sheet hot forming heating, not easy to produce bubbles and deformation; Regenerative plate hot forming heating, easy to bubble deformation.

4, soft baking identification: good acrylic plastic blister word production sheet baking soft even after sticking together can be separated, and poor material baking soft paste together is very difficult to separate. Pure new acrylic sheet to paint, ink adaptability lasting; The regenerated board is sensitive to paint and ink, and it is easy to produce silver lines or cracks.

5, soft rubber edge identification: new plate and good materials factory are packaged with soft rubber edge, in order to prevent rubbing. So this can be used as a way to differentiate between recycled materials and new sheets.

6, quality identification: good plate manufacturers usually provide sample and actual products, you can compare and check according to the color and some parameters, it is also very easy to identify.